Wireless Independent Noble Gas Sampler

A summary of my contributions to the WINGS project during my time as an undergraduate research assistant in UT Austin's RadLab under Dr. Derek Haas.

Published on April 24, 2023 by John Lyle

Design Programming Analysis Electronics

Summary

Problem Statement: The primary goal of this project was to create a wireless noble gas sampler fleet that was both low cost and easily portable. This project was handed off to myself and a few other undergraduates from a previous group of undergrads to fix a few things with the design and then finish manufacturing the rest of the gas samplers.

Project Background: Underground nuclear weapons testing commonly releases a radioactive isotope of xenon as a byproduct of such tests. Since noble gases travel through soil into the atmosphere, these gases are a great way to detect nuclear weapons tests. Current solutions for noble gas sampling require incredibly expensive machines that are nearly impossible to set up in remote locations. By creating a cheaper and portable solution for collecting samples, we can instead ship these samples back to labs to be tested. Another motivation behind this program was to create improved atmospheric transport models for the gas studied.

Project Timeline: I joined this group in May 2022 where we were tasked with adding a few finishing touches to the design and manufacturing 4 more of the sampling units. In my first few weeks on this project I spent a lot of time familiarizing myself with all aspects of the design and assembly process. By doing this I helped myself better understand how the gas sampler worked and more importantly I caught multiple key design flaws in the sampler that required drastic changes in order to remedy. After creating fixes for all of these flaws I assembled and documented the assembly procedure for the first of 5 samplers to be built.

Next I moved onto the software updates that had to be implemented to account for changes in the design while the rest of my team assembled the other 4 units. This software was primarily written for an Arduino Mega and the Blynk web interface that was used to control the samplers. Once the software had been updated I began performing testing on the samplers in order to validate the assembly and design changes.

Once assembly was complete the samplers were used in an irradiated gas release at the Nevada National Security Site in November 2022. The data collected by these tests has since been used in multiple papers. The conclusion of my efforts on this project was a poster presentation at the American Nuclear Society Student Conference at UT - Knoxville in April of 2023.

Basic Design Background

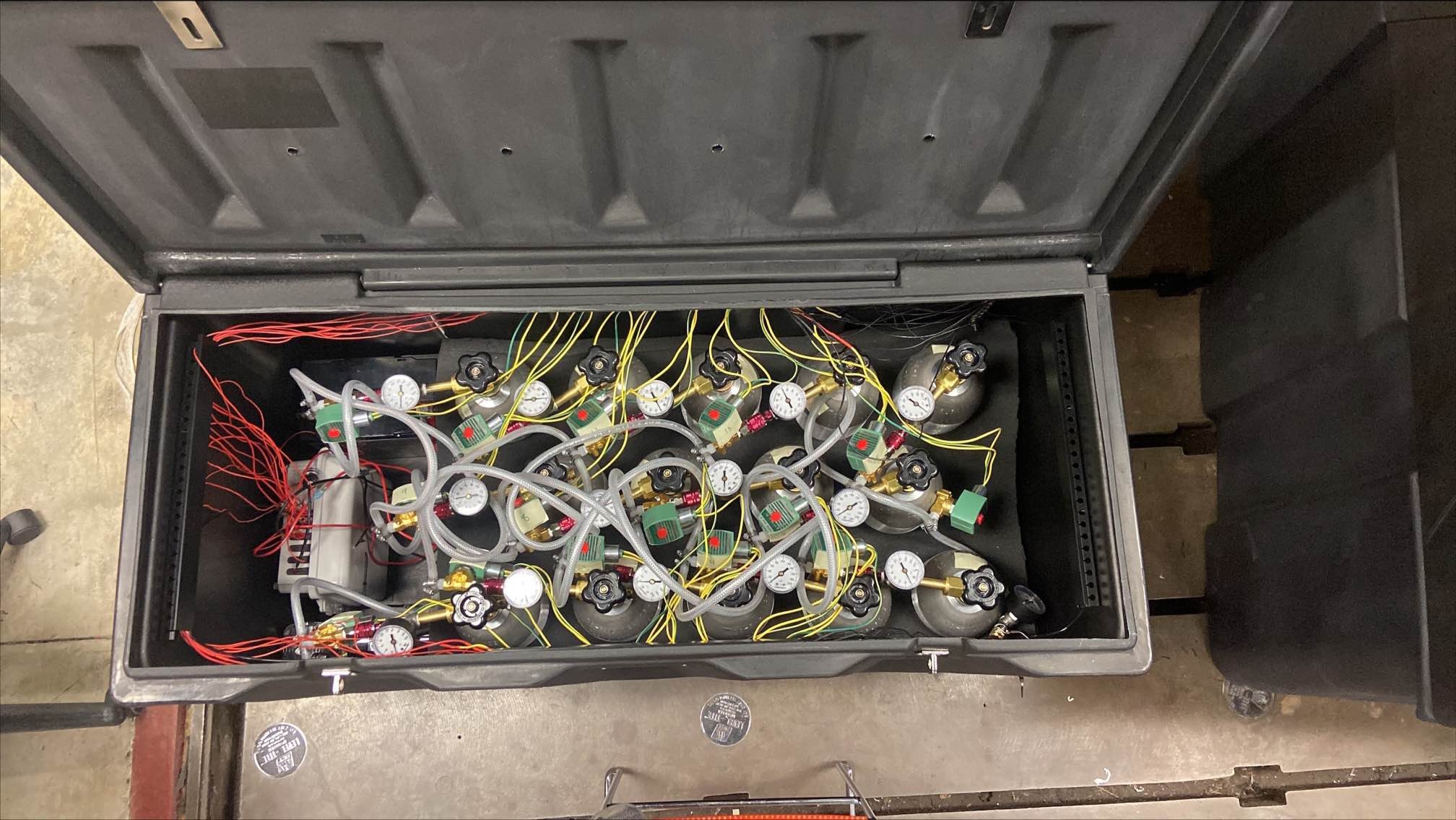

Mechanical Design: All components of the sampler were housed in a 4’x2’x2’ tank. The sampler contained 14 3.5 liter canisters for holding samples at 135 psi. Each canister had a solenoid attached to the end of it for controlling when it would fill or empty. The canisters were pressurized by a pump that pressurized a main line connected to all 14 solenoids to fill the tanks. There was also a solenoid attached to the main line for venting to the environment. The electronics controlling the operation were housed within a control box mounted to the lid. The sampler also contained a 12 volt battery for powering the sampler.

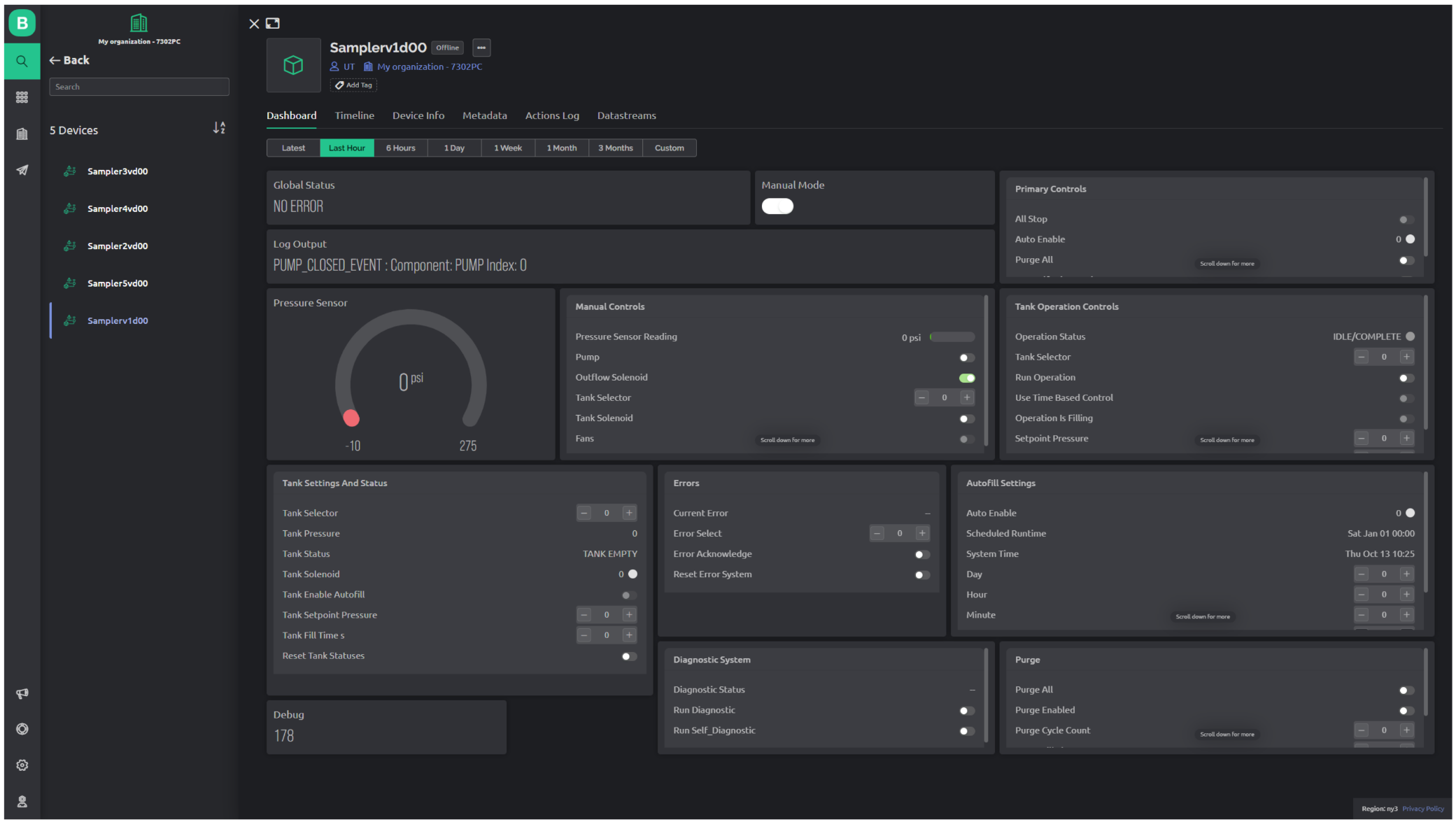

Electronics and Software: The sampler was controlled by an Arduino Mega 2560 that was connected to an ESP8266 unit for Wi-Fi communications. A Blynk web interface was created for controlling the sampler fleet from anywhere with an internet connection. The web interface shown below could be used to set sampling schedules, set pressures, and track sensed errors. The Arduino controlled a set of relays which in turn controlled the solenoids.

Blynk Web Dashboard

Sampling Procedure: For a sampling run the interface was used to select a start time, interval between samples, and set pressure. Once this was selected at each of the times 2 tanks would simultaneously be pressurized to the correct pressure and then the main line would be vented. This process would continue until all tanks were full. The tanks were filled in pairs to compare the new noble gas detection method compared to pre-existing methods.

Individual Contributions

Design Flaw Identification and Fixing: While acquainting myself with this project, I found many flaws that would have greatly hindered the operating abilities of the gas samplers. Once I identified all of these flaws, I then designed solutions for each of them.

1. Incorrect solenoid selection: When examining the data sheet for the solenoids I noticed they were only capable of holding to the desired rated pressure of 135 psi in one direction. This would mean that samples would leak once the main line was depressurized. I selected a replacement component that was a normally closed globe valve that would automatically close in case of power loss to preserve the sample. This component would satisfy pressure requirements and was significantly cheaper however it took 5 seconds to completely actuate.

2. Inadequate pump relay: When reading through assembly documentation there were notes about past failures of the relay controlling the pump. After further examination I determined the relay was not capable of controlling the voltage or current of the pump so I selected a more capable relay that would fulfill these requirements.

3. Tank Re-Organization: The samplers were intended to have the tanks replaced between sampling runs so it was desired to be able to quickly swap out all 14 tanks. The previous design was very complicated with poor cable routing which would lead to slow replacements and the possibility of tanks being hooked into the wrong solenoid. I designed a new internal support structure for a new organization method that greatly streamlined the tank replacement process and centralized all of the cable routing.

Old Tank Layout

New Tank Layout

Software Contributions: In order to account for the actuation delay of the solenoids, a delay in a few areas of the code had to be created. Since the Arduino is a single-core MCU, I had to learn how to do simulated multi-threading in order to allow other functions such as error checking to run during said delays. In addition to this, I also fixed various bugs with the web interface as well.

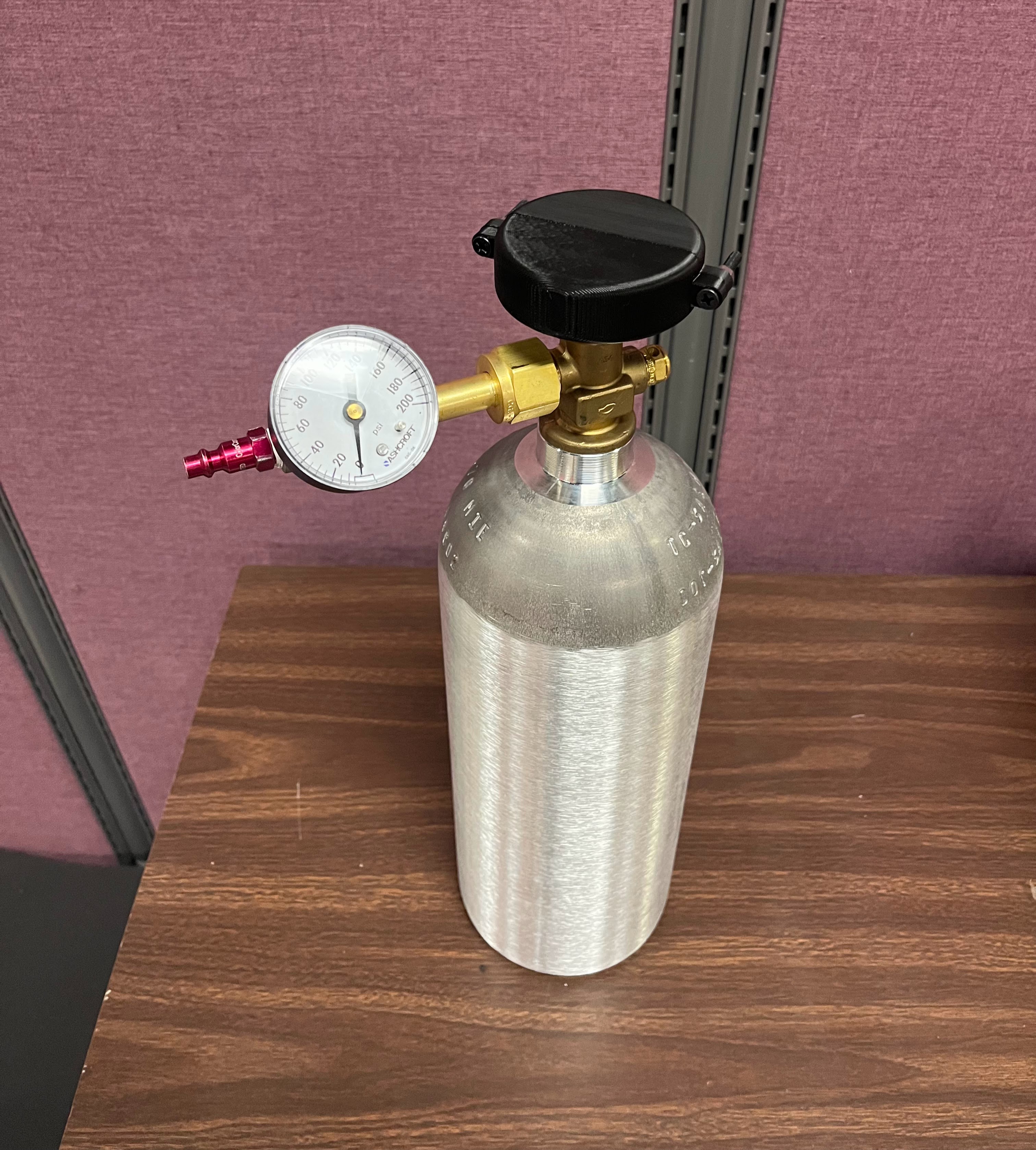

Safety Cap: It was important to have a method of identifying tanks full of irradiated samples and ensure that they couldn’t be accidentally opened. I designed the safety caps shown below to remove the possibility of accidental sample release.

Safety Cap

Academic Presentation: Since I had the most knowledge around the WINGS systems I was selected to give a poster presentation on this project at the American Nuclear Society Student Conference. The abstract and poster I created can be found below.

Key Takeaways and Skills Utilized

This project was one of the first true engineering projects I got to be a part of. I gained so many valuable experiences from it such as CAD, programming, and interpreting engineering requirements. Presenting an academic poster was also incredible to be able to do as an undergraduate. My biggest takeaway from this project was to “trust but verify”. This message is something I applied to requirements given to me for the system as well as the system handed over to us. By verifying the previous work I found many key flaws that may not have been found if I hadn’t.

Skills Used

- Arduino programming

- Circuit Design

- Solidworks

- 3D Printing